Ecological production of concrete pipes with a background in agriculture

The Austrian concrete manufacturer, Betonwerk Koch, focusing its main activities on the production of cost-effective sewerage systems, demonstrates by a photovoltaic system installed on the roof, a concrete processing plant, a bio-composting plant, creative ideas for reuse as well as stork towers that you may not only talk about environmental protection and sustainability but also live accordingly.

Betonwerk Koch GmbH, based in the Austrian town of Mattersburg, is specialized in cost-effective sewerage systems and, in particular, in the manufacture of concrete pipes and concrete manholes for the disposal of wastewater. The company premises covering just over 13 hectares provide space for the production facility including mixing plant and concrete silo, the quality control and development departments, the administration building, the recycling plant, the storage area, and the company‘s own vehicle fleet comprising five trucks. „We ensure our flexibility by our own transport fleet,“ Dipl.-Ing. Josef Martin Koch states. „In this way, we are in the position to change delivery dates on short notice.“

The portfolio includes more than 1,400 different items – almost all of them are in stock at the company site, being immediately available. The company primarily supplies local civil engineering companies with the pipe and manhole products in the weight range from 15 kg to 20 tons. A special product of the manufacturer is the COMPOair aeration pipe for composting systems. The pipe is in demand across the world and is sold far beyond the Austrian border. „This concrete pipe can be regarded as an absolute niche product,“ reports Dipl.-Ing. Josef Martin Koch.

COMPOair and the internal composting plant

Betonwerk Koch has developed the COMPOair aeration pipe for composting systems in cooperation with Compost System GmbH. The product concerned is a concrete pipe which is installed in the rotting area directly. An equal distribution of air is ensured by systematically arranged nozzles, resulting in an ideal composting process.

The range of concrete products for composting plants also includes the so-called Varioblock, which can be assembled like Lego bricks to storage boxes and separating walls. In this way, an expensive foundation is eliminated. The innovative modular construction system allows an adjustment to any plant size, and thus the precast products are of interest for customers in China, India, Latin America, and Africa, too. Anyone who would like to see a reference plant need not travel far because there is one right on the company‘s factory premises. In 2017, a composting plant was installed on the company site for composting 2,000 tons of organic fertilizer per year. „In this way, we diminish our ecological footprint,“ says Dipl.-Ing. Josef Martin Koch. However, the ecological commitment of the family-owned company reaches far beyond the operation of a bio-composting plant.

Photovoltaics, recycling and stork towers

A photovoltaic system with a capacity of 50 kWp is installed on the roof of the concrete plant and supplies the factory with environmentally friendly energy. Moreover, it is considered as a matter of course by the company: to have an own concrete processing system for the recycling of residual concrete. And if once a pipe should be produced with wrong dimensions or any other defects in manufacturing should occur, it will be creatively used as raised bed or plant plot.

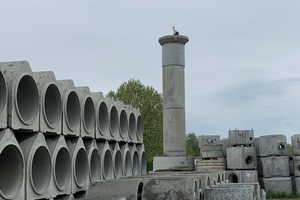

A peculiarity can also be discovered on the concrete pipes rising up to the sky, because they have been breeding place for a stork couple since 2004. Every year in spring, the migrant birds return to Mattersburg and build their nest. The storks obviously feel comfortable on the premises, are very trusting and have long since become a „trademark“ of the manufacturer of precast products. Therefore, the Koch family decided to provide even more storks a breeding place and installed additional pipes for the birds specifically. However, the entrepreneur made the well-intentioned plan without the resident stork couple which claimed the entire concrete plant as its exclusive territory and did not tolerate any other storks there.

But the precast producer‘s love of animals is also expressed in other details. Along with dog „Filou“ who freely moves on the grounds and serves as a „chief happiness officer“ for the workforce, the company site is also habitat for fallow deer and dwarf cattle. The question on how these hobbies can be managed in terms of time, Josef Martin Koch explains: „Many of our employees have an agricultural background and are happy about a distraction. There is always somebody who lends us a hand when it comes to the animals.“

Customized production

With the especially designed „Koch“ high-performance concrete, the family-owned company pursues the objective to meet their own quality standards. The raw materials are stored in a concrete silo. Two concrete mixers are available for the next processing step, bucket conveyors principally provide for concrete distribution. The company uses both flowable concrete mixtures hardening in the mold and no-slump concrete mixtures for immediate automated demolding. Concrete manholes can be supplied in any variations and individually adapted to any installation site and customized accordingly.

A core component of the production line is the Teksam SPSM 1000 dry-cast machine which can be used for concrete products weighting up to 1,000 kg with a height of 1,000 mm. The machine comprises a feeding unit, a press head, and a manipulator for demolding. A mbk reinforcement welding machine of type 60-440/36-3000 is used at the Koch concrete factory for welding shapes in various cross-sections with cage diameters of up to 4,400 mm and cage lengths of up to 3,000 cm.

Family-owned business and training company

At present, Betonwerk Koch has a workforce of about 40 people. The staff is made up of three employees in the field of technology and quality assurance, two sales employees, two persons in bookkeeping, and the staff members in the field of production and vehicle fleet; in addition, the company employs three trainees. „Without apprentices there is no future,“ states general manager Ing. Josef Koch, whose parents founded the concrete plant in 1955 and who is running the company now together with his wife and son, Josef Martin Koch.

With his son entering the company, the third generation is actively engaged in the family-owned business today. Even when driving to Mattersburg, Betonwerk Koch already characterizes the townscape. Because, on the occasion of the „150 years of railways in Burgenland“ special state exhibition, an original locomotive was assembled using precast elements manufactured by Koch and is now decorating the main roundabout of Mattersburg.