powermanager power monitoring software

with direct cloud connection

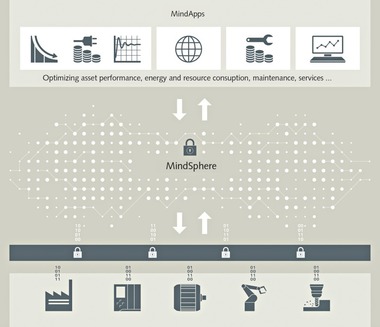

With the new version of the powermanager power monitoring software, power data can now be directly transferred into open, cloud-based IoT operating systems such as MindSphere. The software is part of the Sentron portfolio from Siemens for energy management in industrial plants and buildings, and assists companies in boosting their energy efficiency and availability. It displays status information and electrical characteristics for complete plants and systems as well as individual devices in a clearly-arranged dashboard and analyzes energy flows. This allows for derivation of optimization measures for energy efficiency and availability and for quick pinpointing of faults in the plants. The integration of data in cloud systems enables the storage, processing and the cross-site analysis of large volumes of data. The power monitoring software is optimally suited for small to medium-sized companies seeking to implement digital energy management. The investment costs are low and can be quickly amortized through savings potential.

In combination with communication-capable protection and measuring devices, such as 3VA molded case circuit breakers and 7KM PAC measuring devices, the powermanager power monitoring software establishes the technical basis for operational energy management according to ISO 50001 and ISO 50003. The scalable and intuitive software can be easily deployed with the available hardware and the existing IT infrastructure. Among other features, the power averages of the characteristics monitored are visualized as graphs showing changes over time on the user’s PC, and load peaks are quickly identified. Through the direct comparison of various processes, loads or system components, inefficiencies can be uncovered. Loads can be allocated exactly and on a cross-location basis to individual cost centers – this enables precise benchmarking, along with optimization of utility contracts. Thanks to continuous monitoring of power distribution, even critical plant states are identified early, and downtimes are prevented. Users can benefit from a considerably higher plant availability and energy efficiency, along with lower costs.

//www.siemens.com" target="_blank" >www.siemens.com:www.siemens.com